Construction Work of the Air Ministry Depot Type Storage and Maintenance Engineering Buildings at Burtonwood Repair Depot Site Burtonwood (Known as BRD Site)

Photos Credit to British Pathe

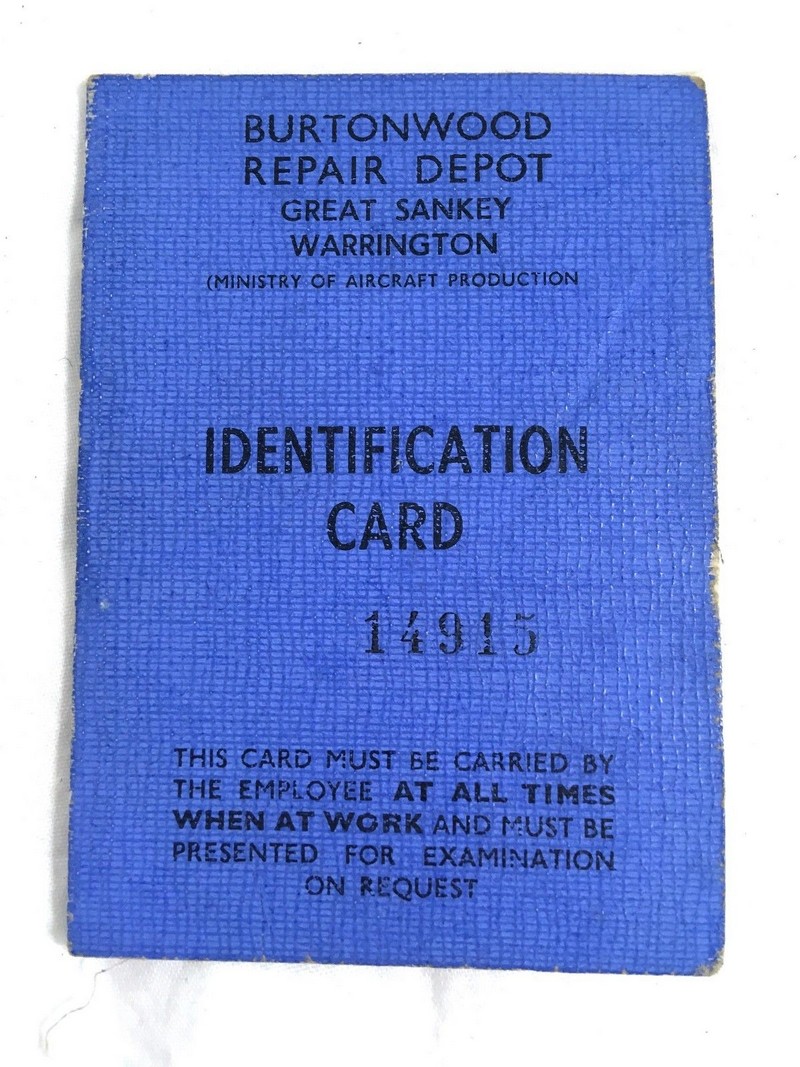

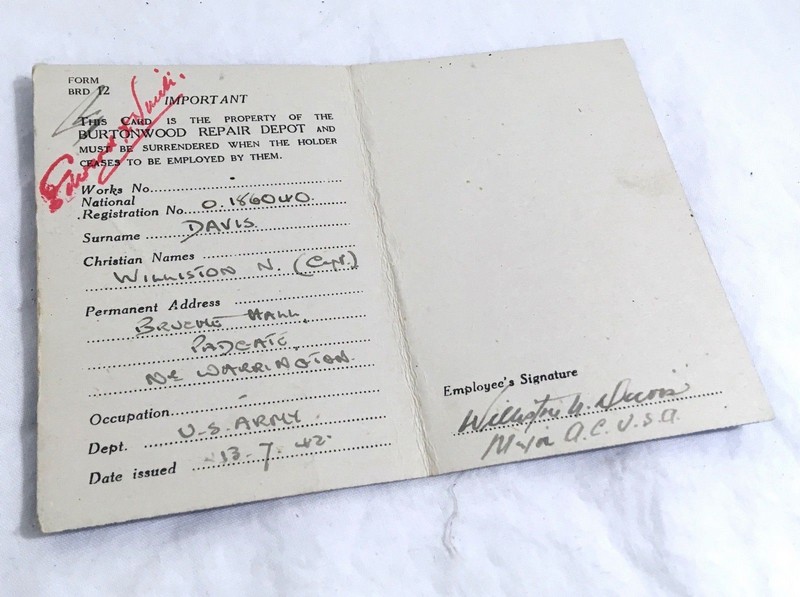

BRD Civilians Pass Book

There was a large number of civilian personnel during WW2 and each had

to have their own BRD passbook. Below is a genuine example of one.

'Proud' Signage of Leading to the Engineering Buildings

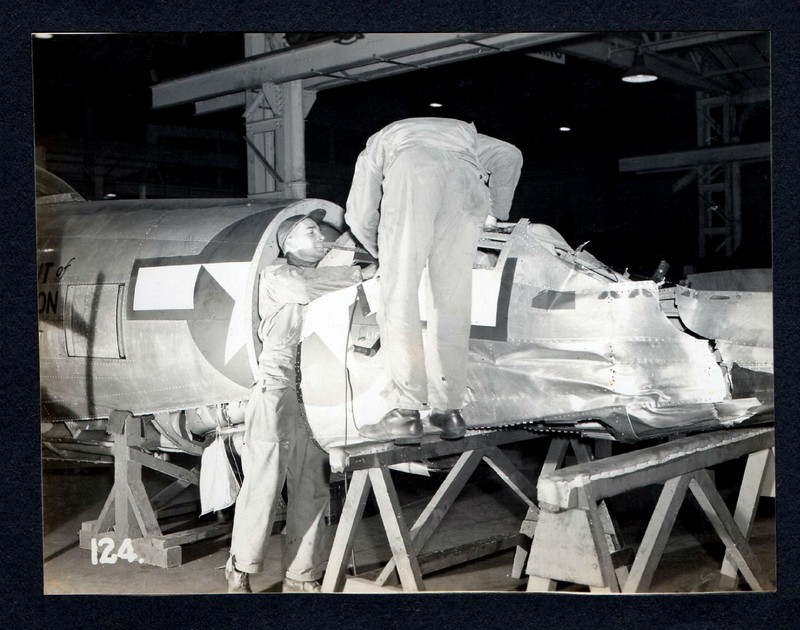

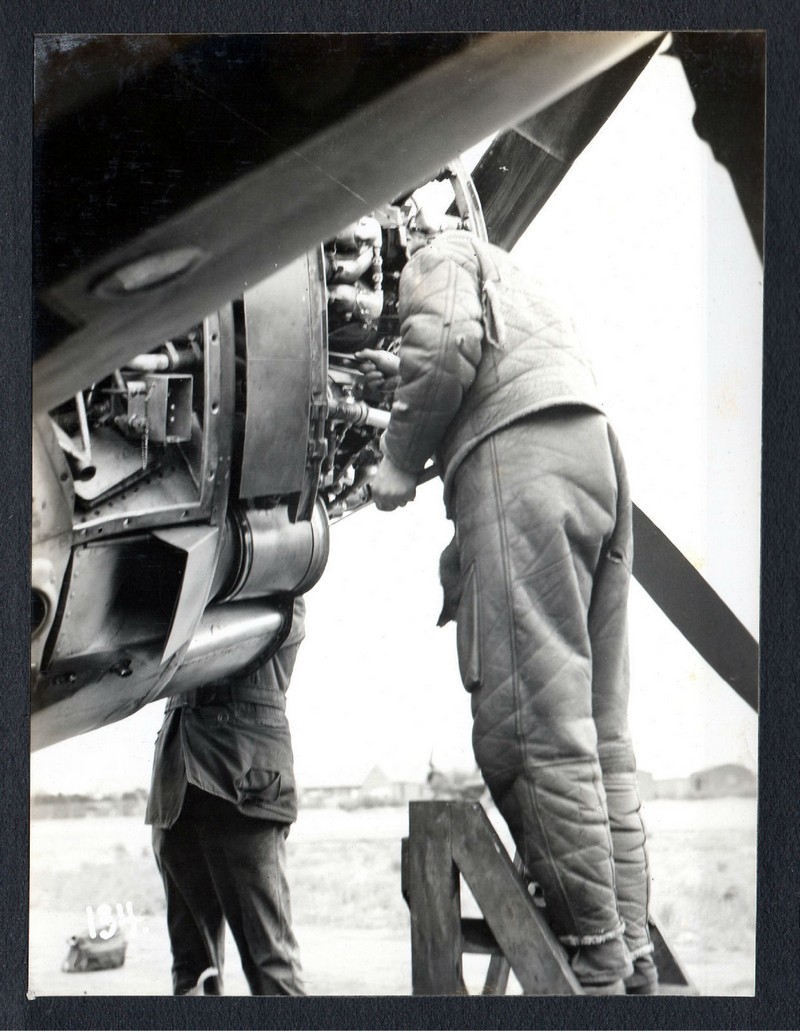

BRD site is basically a factory for aircraft maintenance and repair. The depot workshops included facilities for the modification and repair of air frames, overhauling and testing of engines, variable pitch props and woodworking and metal work.

Air frames were delivered on board ship across the Atlantic and once they were at BRD site, they were modified and assembled on site. They were then towed by tractor to the airfield for flight testing.

Due to the difficulty of getting spare parts from the US, BRD had its own production facilities to manufacture anything that may be required.

Mary Ann site was part of BRD site. Large 4 engined bombers were repaired there because they could not enter BRD site due to their sheer size, although the engines and systems were maintained at BRD site. Smaller aircraft, such as P-38, P-51 and P-47 were assembled on BRD site.

Burtonwood Repair Depot (known as BRD site)

Burtonwood Repair Depot (known as BRD site) was a factory site built to the South East of the airfield and was erected in 1939 & then occupied in 1940 under the control of the Air Ministry (Not the RAF)

The site was later taken over by the Ministry of Aircraft production (MAP) and in 1942 was transferred to the USAAF.

The main entrance to BRD site was gate 9 sited at the South End of Burtonwood Road opposite site 8.

The headquarter buildings was sited just inside the main gate (9).

1 Type 'A' aircraft hangar was constructed on BRD site.

This type of hangar was designed in 1924.

The hangar featured a steel frame with longitudinal ridge and valley trusses for the roof with reinforced concrete and brick infillings for the walls.

The span was 122 feet and the length was 249 feet.

The hangar and associated workshops covered 722,000 square feet.

Along the rear of BRD site were over 30 aircraft engine test rigs running 24 hours a day 7 days a week.

The sound of these engines could be heard up to 2 miles away.

The site also had its own Railway Sidings, Locomotive shed & a short branch line connecting into the main Liverpool to Manchester Railway Line.

Fairey Aviation Company was the parent Company to BRD site.

On September 1940 Curtiss Mohawks arrived there in early 1941 & also at this time technicians from Brewster, Curtiss & Douglas Aircraft Companies arrived there.

4 Subsidiary firms operated on BRD Ltd under Technical guidance being Rovers Radials, Rollinson Radials, Sunbeam Liquid Cooled & British Overseas Airways Corporation.

The site was officially handed complete control to the USAAF on the 21st of October 1943.

The Air Ministry built 10 equipment type depot stores buildings on BRD site for the use of warehouses and engineering workshops.

They were built in parallel rows 5 to each row.

Each building having 10 smaller type buildings attached to them, 5 on each side coupled together forming continuous rows of workshops.

10 equipment-type Depot buildings were built at BRD Site.

They formed 2 parallel rows two sets of 4 coupled together with 2 singles at one end forming continuous rows of workshops and warehouses. They were constructed to air ministry drawing number. 10648/38

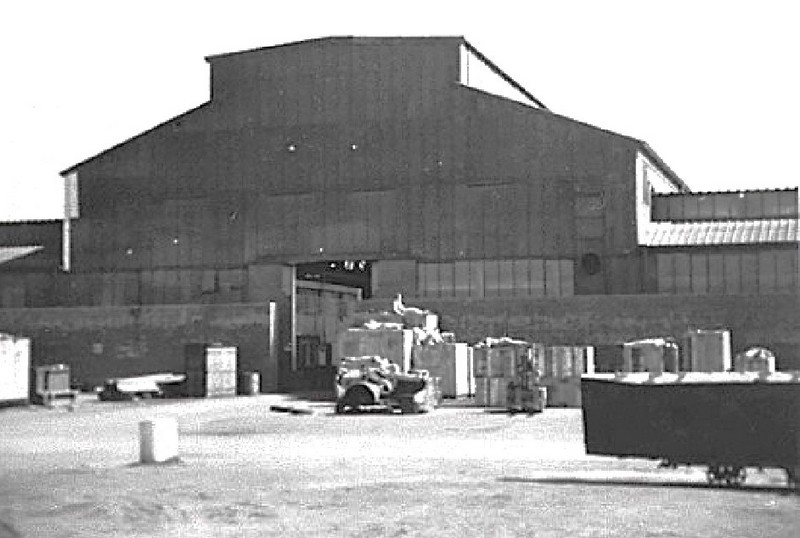

1 of The 10 Equipment Buildings at BRD Site

Building 8 is the headquarters and Office Block for [BRD] Burtonwood Repair Depot

During the late 1950s, this building was used as the USAF Dependents School, after moving from Site 1

In the foreground is gate 11 which is the north entrance into the BRD site

Behind the gate is Burtonwood Road

In the far background is gate 12 leading to the Airfield and site 8

Building 94 is the Gas Decontamination center

The Square Opening is for the Contaminated Clothing

Shoots with the vent to the right

The side elevation of the Gas Decontamination Center and Clothing Shoots

The Gas Decontamination Centers were also known as Gas Cleansing Stations

In the right foreground is the Gas Decontamination center, and in the background are the warehouse workshops

B-17 in the Process of Scraping in Front of One of the Engineering Workshops at Burtonwood Repair Depot [BRD] in WW2

The same Engineering Workshop 70 Years Later at the BRD Site

A row of 4 Engineering Workshop buildings, in the foreground, is Building 100

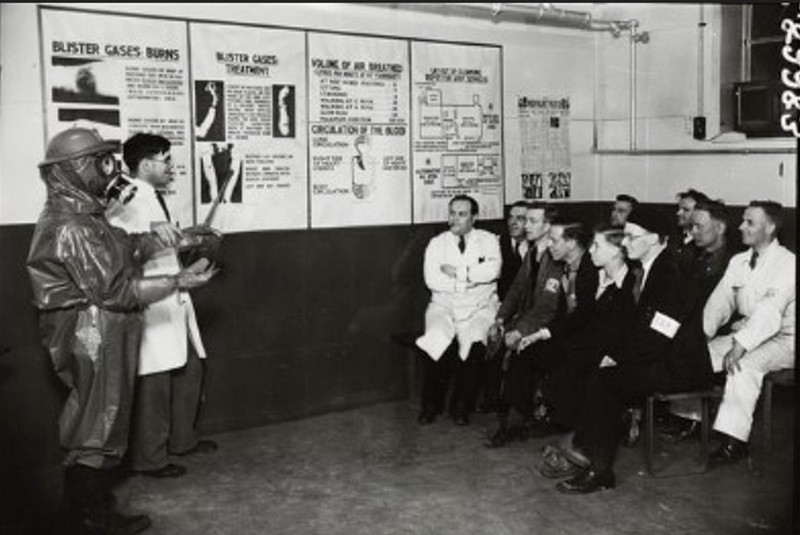

The photo shows a first aid squad, laden with first aid packs, water bottles, and a stretcher, leaving the first aid post at the double to attend an incident at the Burtonwood Repair Depot on 2 June 1942

The caption on the reverse of the photograph reads:

“The male nurse in industry. Pix shows Mr. C.A. Kissack (Chief Warden, A.R.P.) lecturing defense workers on gas decontamination at the BRD Site on 2 June 1942"

A group photo of Specialized Aircraft Engineering Technicians of the USAAF at the BRD Site in 1944

A group photo of Stanley L Kaminski and work friends of Number 1 Maintenance Division Section 16 at the BRD site

Photo credit to Stanley L Kaminski of the 8th USAAF

A light Anti-Aircraft Gun Position

A group photo of Americans at the Burtonwood Repair Depot Site

Building Number 100

Building number 17 Loading bay

Building number 149 Fire Assembly Point

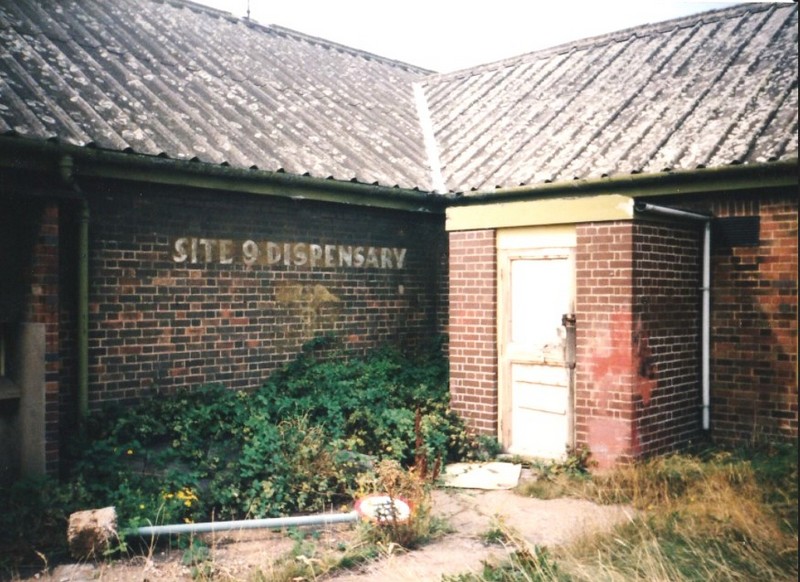

Site 9 Dispensary

Site 9 Dispensary

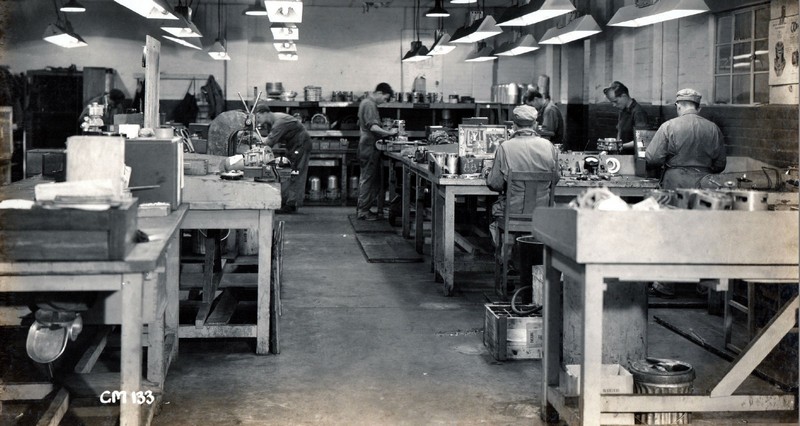

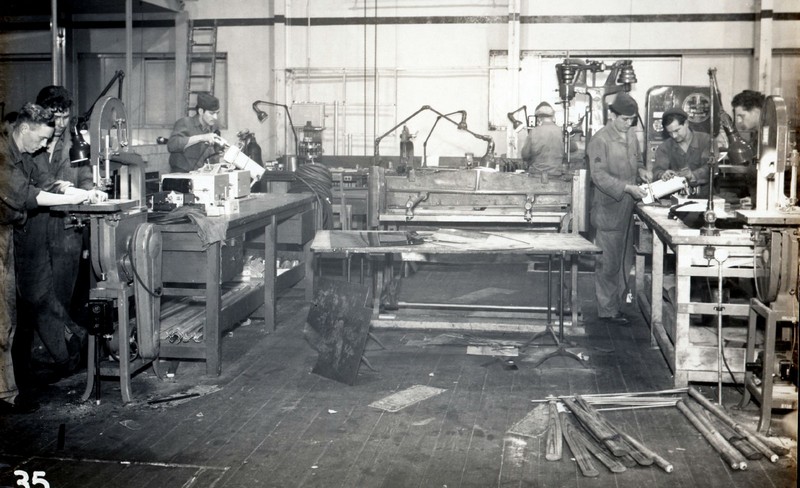

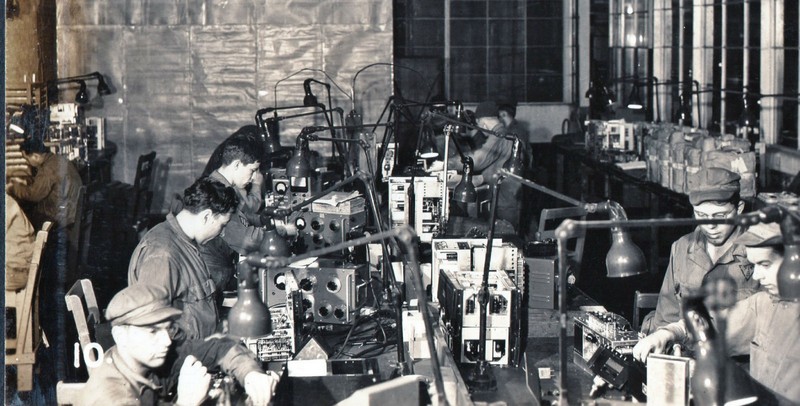

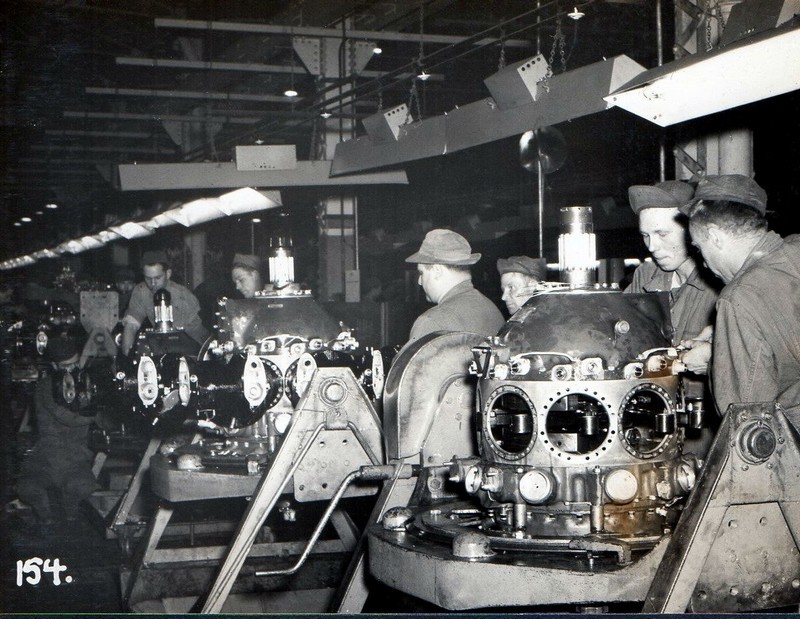

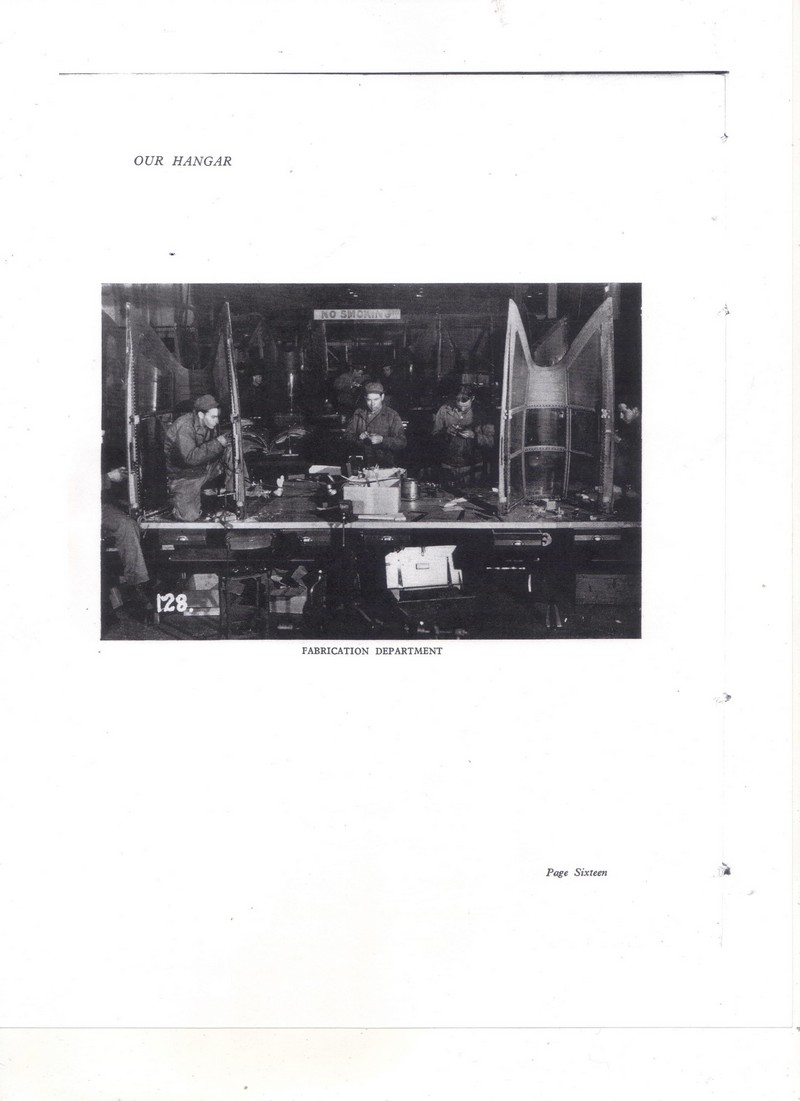

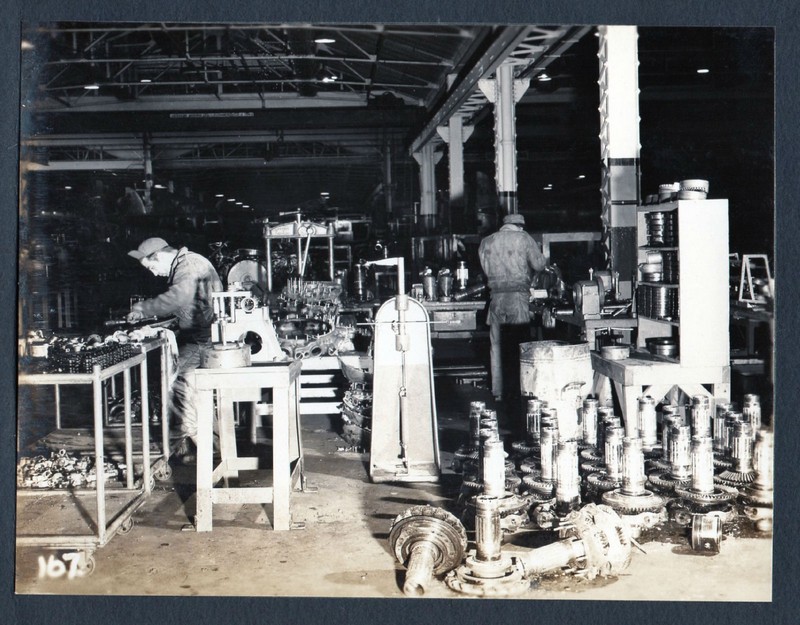

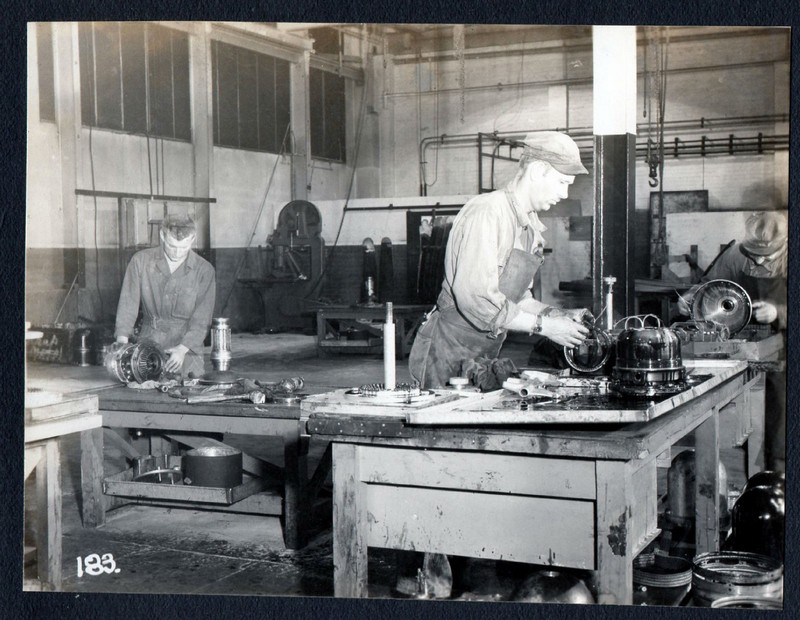

The following photos illustrate the engineering and production facilities at BRD site.

Reduction gear cases for radial engines in the foreground

and induction manifolds and Radial Engine

Cylinder Heads in the Background

Photo 217 Machine Shop

Photo 224 50 Calibre Machine Gun

Photo 35 Wood Shop

Photo 16 Radio Repair

Photo 10 Radio Repair

Photo 115 Maintenance P-38 Lockeed Lightning

Photo 140 Storage/Engine Maintenance

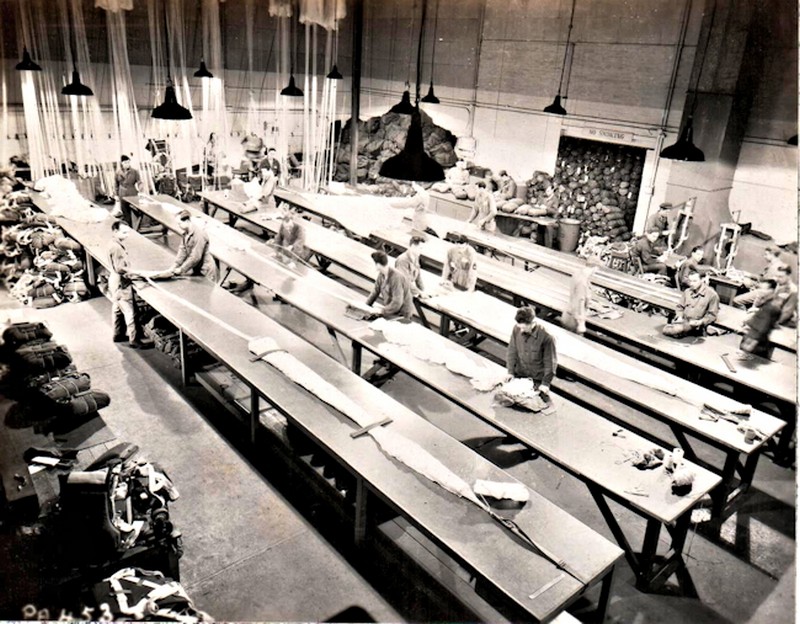

Photo PA 461 Parachute Inspection & Packing.

Note: In the foreground of the photo are crash test dummies.

Photo PA 453 Parachute Inspection & Packing.

Photo 154 Engine Overhaul Shop.

Photo 176 Prop Section

Photo 185 Hydromatic propellor barrel assembly

Colonel OTT base commander WW2 pictured

far right (anyone know any of the other guys?)

BRD Site established manufacturers courses for civilian and RAF personnel and on 7 July 1942, the number 21 school of technical training was formed.

The school was under the control of the MAP Ministry of aircraft production that had three courses being hydraulics, American engines, and electrics.

At first, the school had 58 students with 11 instructors, and by early 1943 the school was running ten courses on turbo-superchargers, cyclone and wasp engines, P-47and B-17 airframes and electrics.

Other training courses included pilot handling, flight engineers, even with the arrival of the United States army air force the training school continued to train their students the, number 21 school of technical training was disbanded on 16 April 1946.

Students of Number 21 school of technical training inside the workshops.

Group photo of students of the number 21 school of technical training

Group photo of students of the number 21 school of technical training

outside one of the air ministry depot type workshops at BRD site.

BRD Engineering Workshops WW2

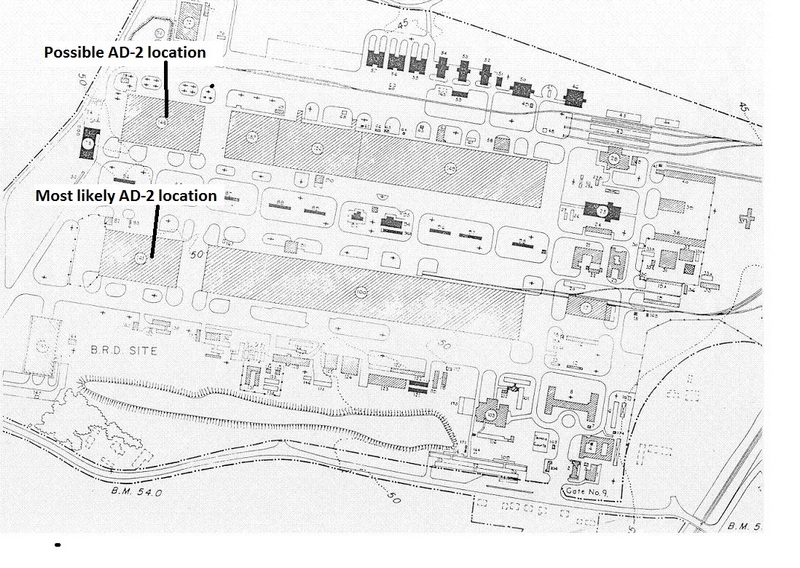

Record Site Plan of BRD Site

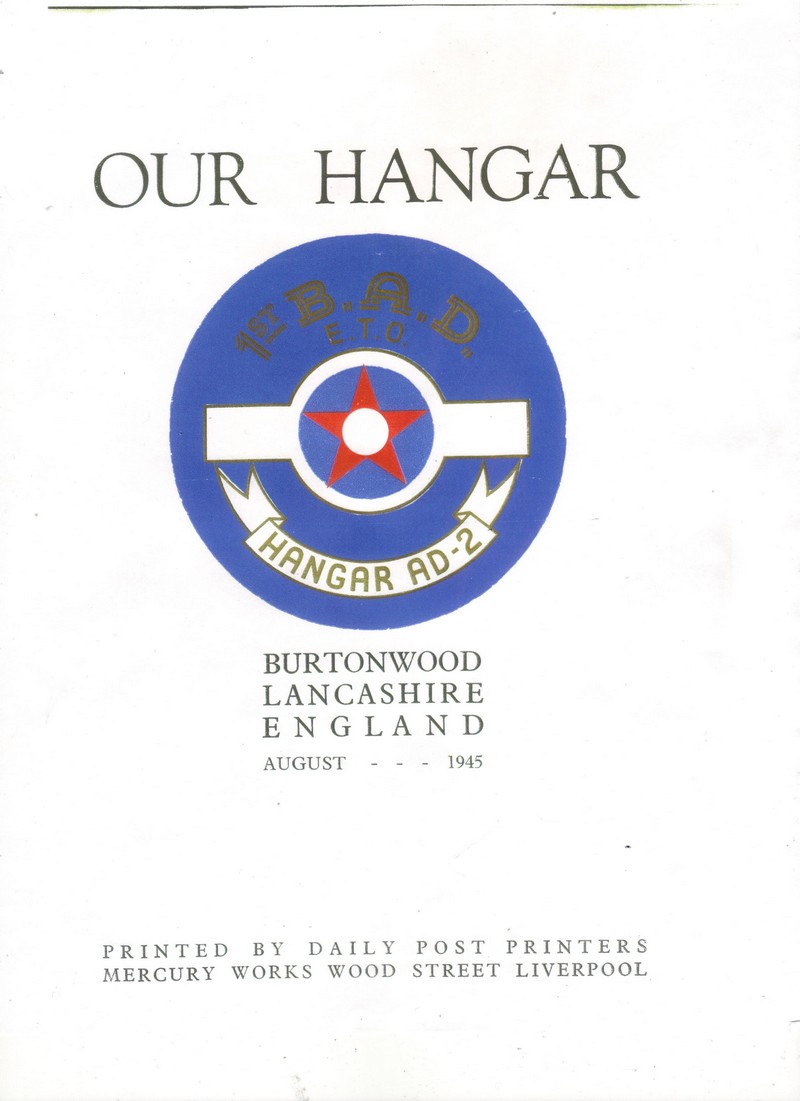

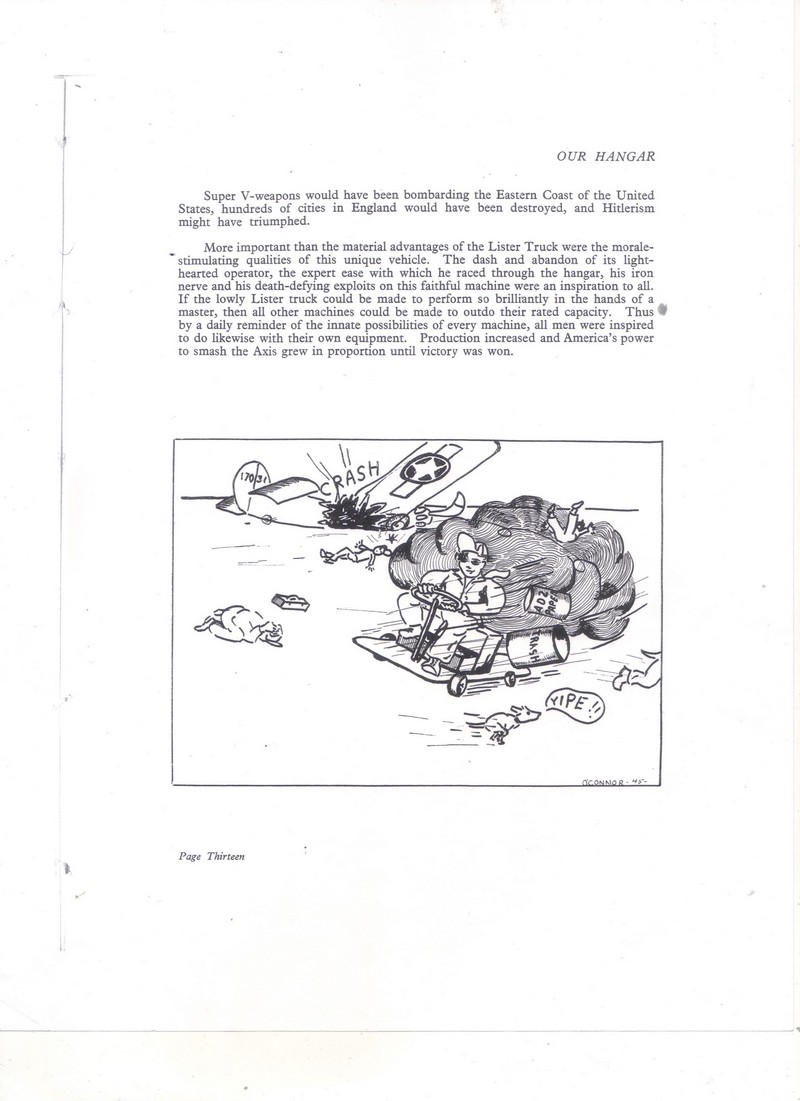

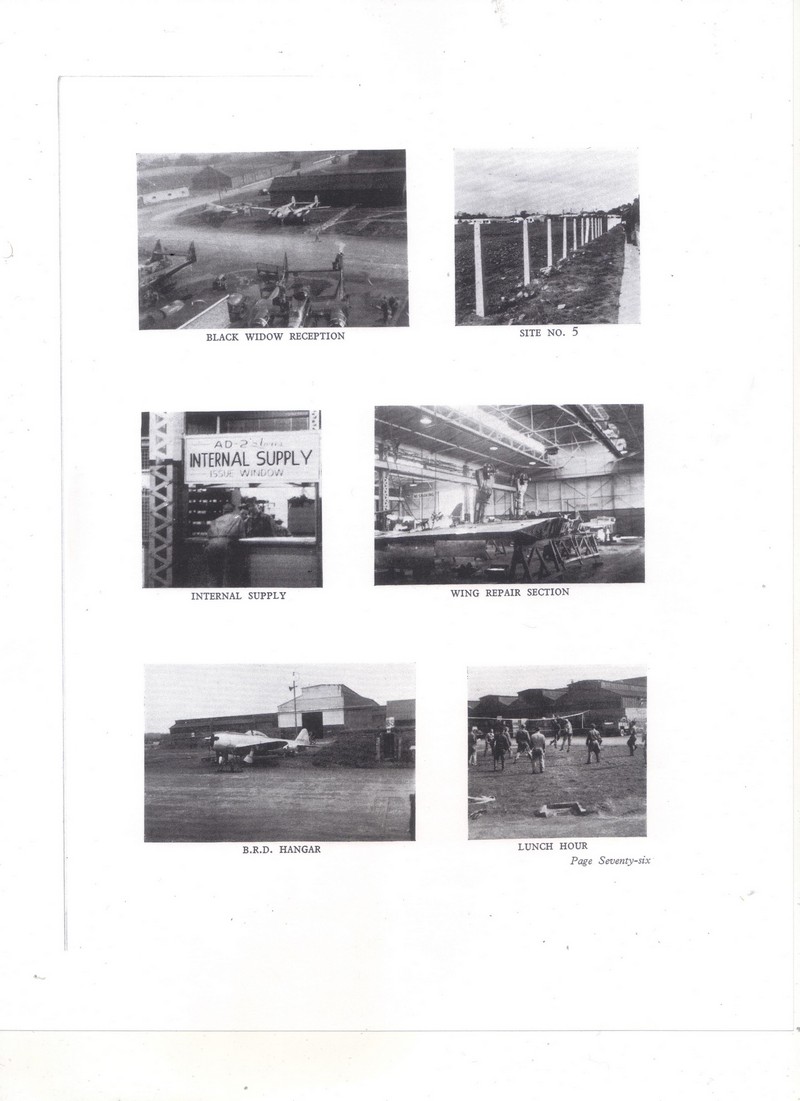

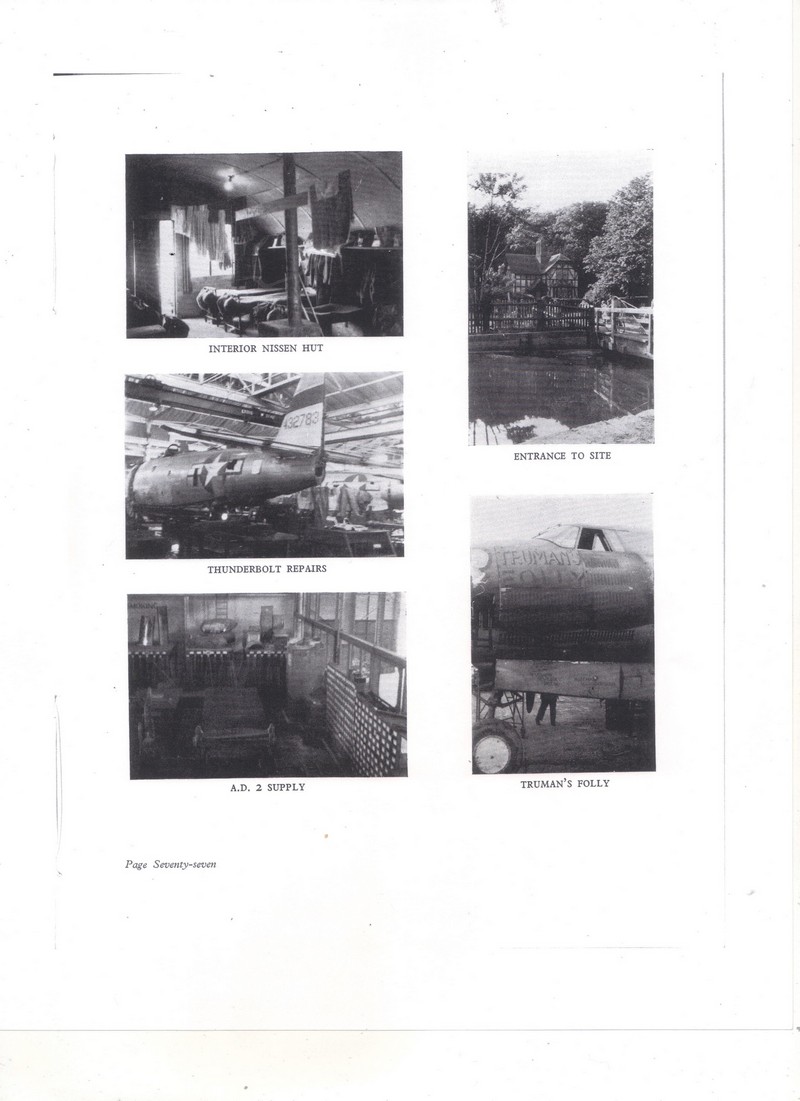

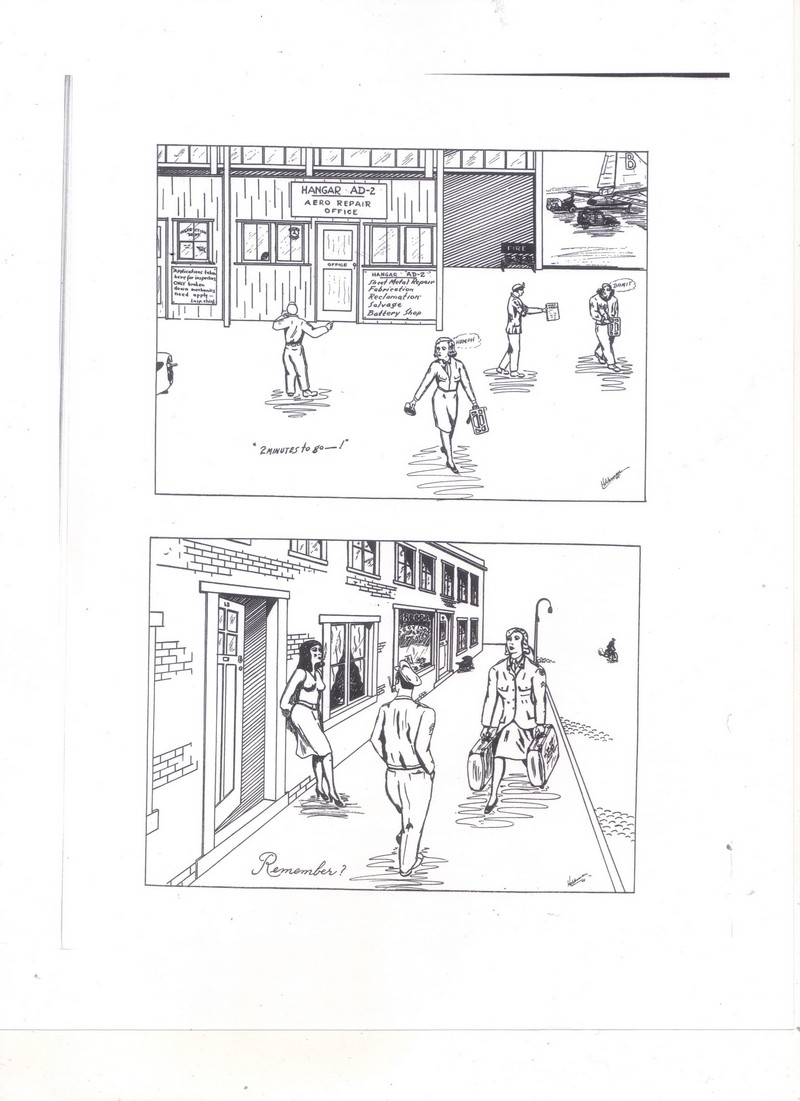

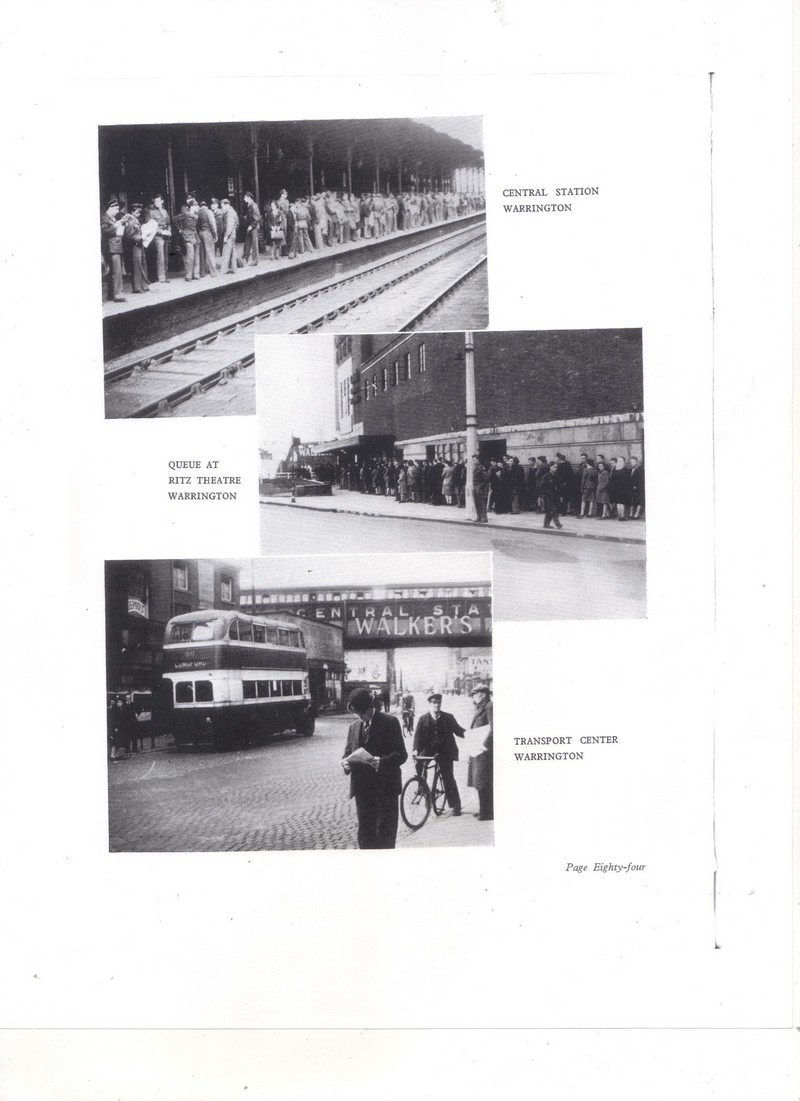

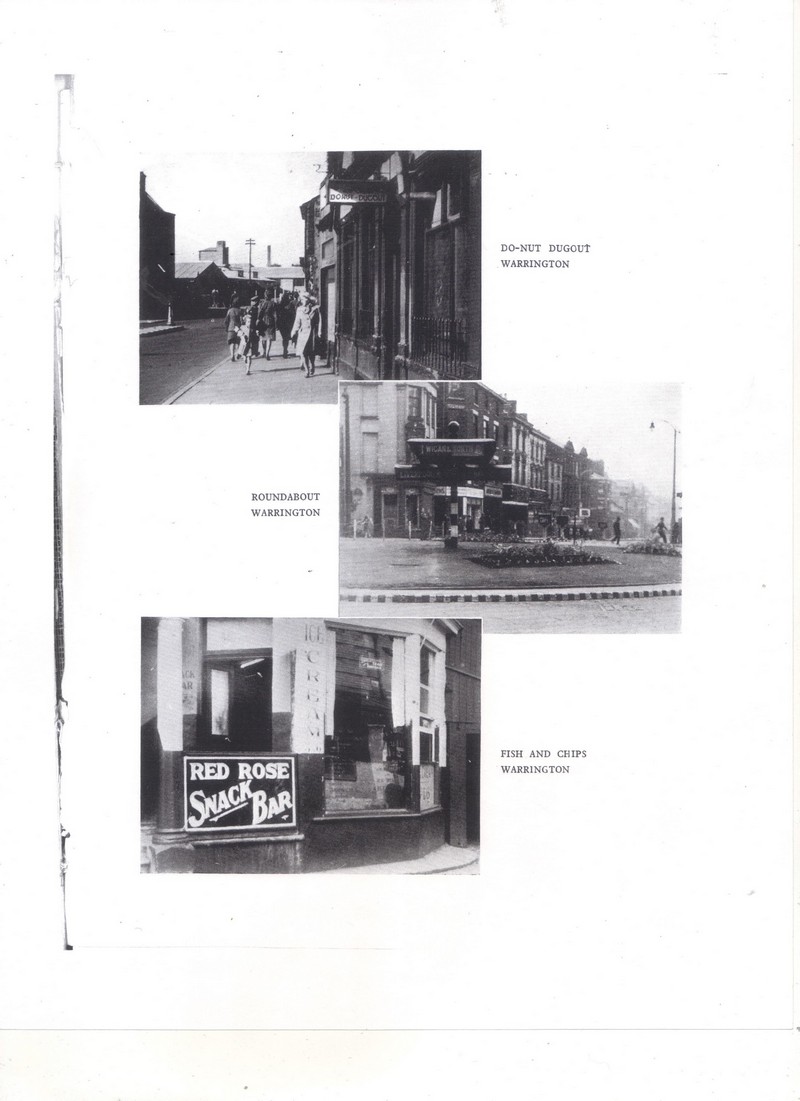

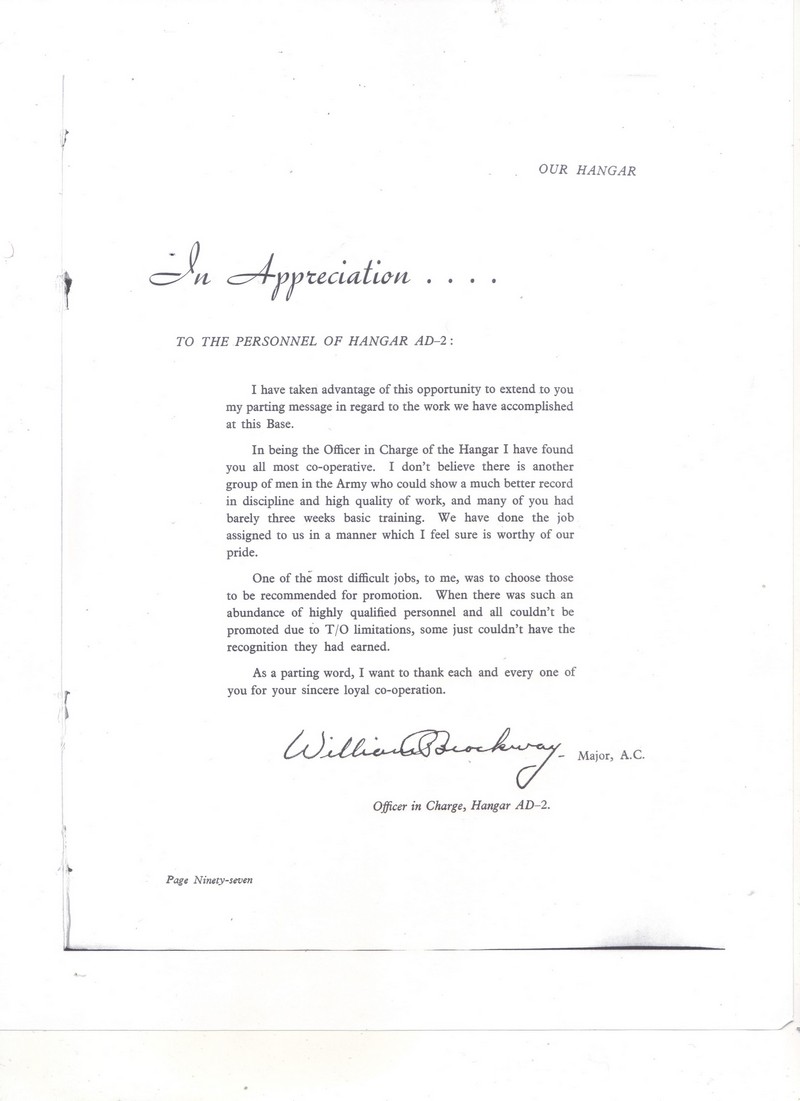

Hangar AD-2 Book on BAD site

The record site plan (above) shows the location of hangar AD-2.

At the end of World War 2 the personnel of each hangar and workshop received a copy of a specially prepared book of their work while service at BAD site before returning back home, very similar to a college Year book.

Many thanks to Terry Kekic and his brother from the USA for spending a very long time scanning and actually sending a physical copy to us.

Terry Kekic's father Frank Georg Kekik was one of those personnel at BAD and served there during World War 2 and the following pages are from his personal copy of that book.

B.R.D. Building legend for above aerial photo 1945

(Please note: Because the building numbers on the record site plan (that we have) are of

poor quality, we have re-numbered the most relevant buildings to the one's shown below)

| 1 Fuel storage tanks (oil) |

| 2 Standby electrical generator & compressors |

| 3 Engine test beds & their associated oil and petrol installation |

| 4 Fuel storage (coal) |

| 5 Central heating boiler plant |

| 6 Rootes Securities Ltd |

| 7 Plating shop, variable pitch airscrew shop & Salford Electric |

| 8 Fitting shop, machine shop, aero engine storage & sheet metal shop |

| 9 Engine repair shop |

| 10 Decontamination & first aid shop |

| 11 Demolition & detonator building |

| 12 Decontamination & first aid |

| 13 sanitary block |

| 14 Aircraft depot repair shop |

| 15 Aircraft depot paint shop |

| 16 Canteen |

| 17 Defence (military) |

| 18 Motor transport petrol installation |

| 19 Aircraft depot erection shop |

| 19a Embodiment loan & main store |

| 20 Maintenance office & store |

| 21 Transformer electrical sub station |

| 21a Scrap metal store |

| 22 Fire & ambulance station & gas defence |

| 22a Petrol pump for motor transport |

| 23 Motor transport office & shed |

| 24 Rail weighbridge |

| 25 Articulated trailer shed |

| 26 Motor transport shed |

| 27 Railway locomotive shed |

| 28 Wood Mill & timber store |

| 28a Road weighbridge |

| 29 Lubricant & inflammable store |

| 30 Headquarters office block |

| 31 Air-raid precaution control room |

| 32 Warden office & emergency air-raid precaution panel |

| 33 First aid clearing room |

| 34 Employment office |

| 35 Hutted camp |

| 36 Main entrance gate 9 |

| 37 Bus depot |

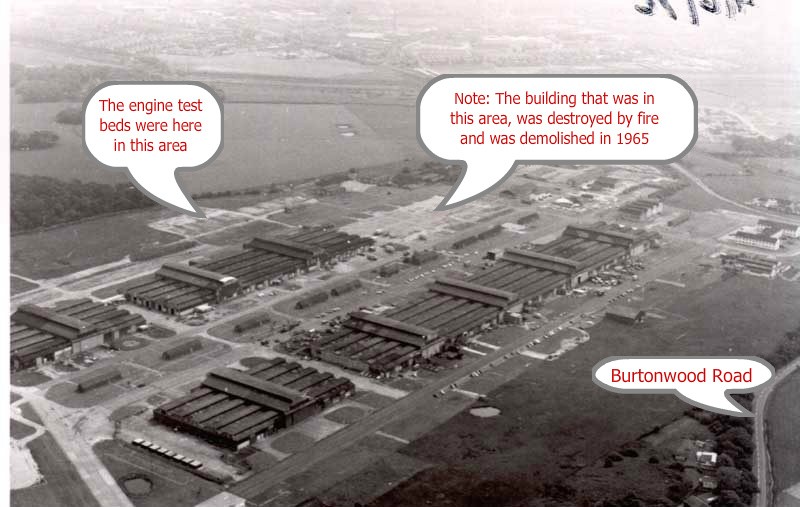

Aerial Photo of BRD Site

Main Gate Entrance to BRD (Burtonwood Repair Depot) Site.

Main Gate Entrance to BRD (Burtonwood Repair Depot) Site 2014

The American flag is raised during WW2 for the transfer of the

Burtonwood Air Depot to the United States 8th Air

Forces Service Command 15th July 1942

Building number 8 on the left of the flag is the Burtonwood

repair Depot site Headquarters, during the late 1950s

this building become the United States Air Force

Dependents School having moved from site 1

Aerial Photo of The Headquarters Building Just inside the Main Gate (9)

BRD site photo taken from site 8 boiler house looking across Burtonwood Road

Air Police BRD site WW2

Railway Branch Line Running East Looking

From the Level Crossing Gates (no longer there)

The two green posts on each side of the footpath supported the gate

across the railway line which ran along the rout of the footpath and

entered site 8 to the rear of where the picture was taken.

Railway Branch Line Continued From Picture Above (going West)

The branch line obviously ran in between the fence posts

The route of the railway (line as above) coming backwards.

The 2 posts can be seen in the distance where the level crossing used to be.

Also, note the 3 GPO cable duct chamber covers.

Railway Branch Line Continued From Picture Above (going East)

Pedestrian Crossing Footpath

During operation the gate was closed to pedestrians

The Rails Can Still Clearly be Seen

Branch railway line Pedestrian crossing Gates

The gates to the Left are towards the main line

The Gates to the Right are towards site 8 at RAF Burtonwood

Photo Credit to Walter Miller

Looking along the track bed towards the BRD site & site 8 at RAF Burtonwood

Photo credit to Walter Miller

The Level crossing gates facing West towards RAF Burtonwood

Photo credit to Walter Miller

A diesel passenger service travels west towards Liverpool

Photo credit to Alan Hart on 29 November 1989

A diesel DMU is passing the branch line junction

Photo credit to:

Anthony McDonnell on February 1987

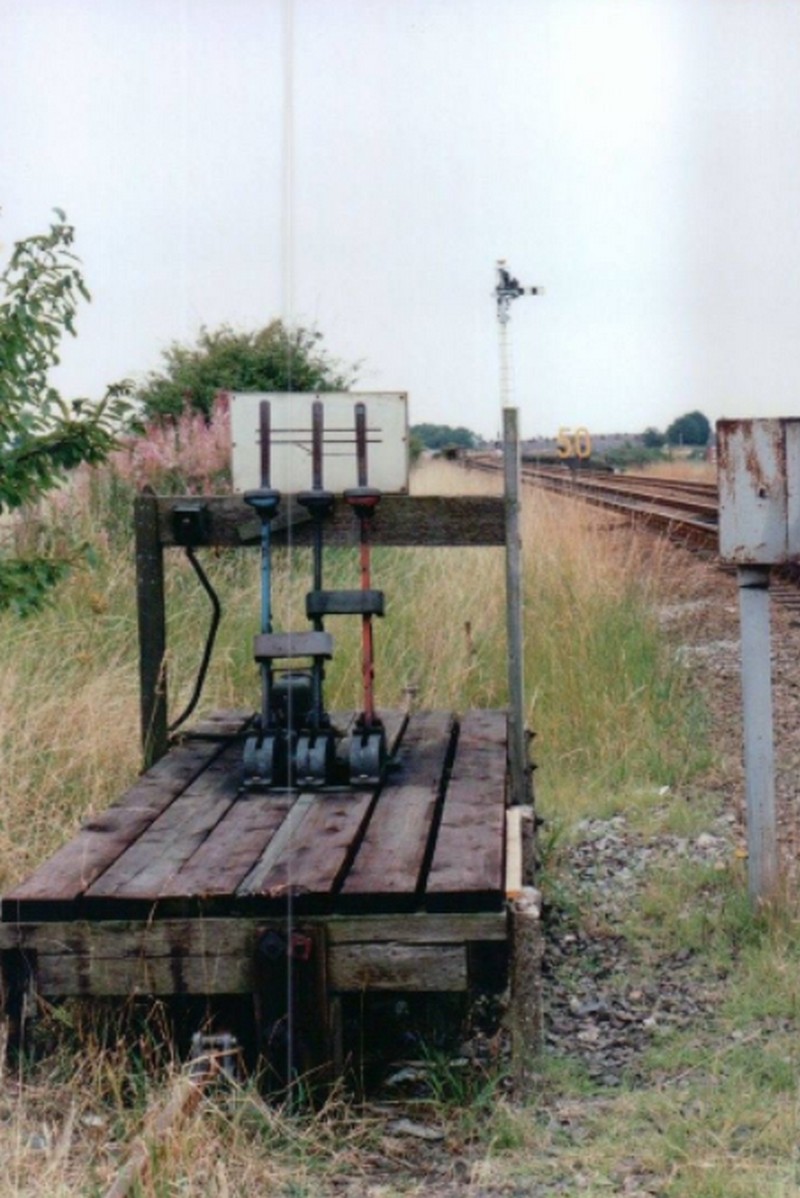

Branch line Junction Ground Frame

Photo credit to:

Marks Railway, Past, and Present Pictures

A signal box was sited here in WW2 to control entry into the BRD site. The branch line had large volumes of traffic in WW2. The signal box was closed on the 24th of October 1965 and replaced by a 3-lever ground frame released by Widnes East.

The ground frame was out of use by May 1993 when the Airbase closed.

Looking East at the branch line Junction

To the left is the branch line signal

The ground frame is behind the Photographer

photo credit to Anthony Mc Donnell in 1970

Looking West at the branch line Junction and signal

The end of the railway line facing East joining the main line rail head

The line as it was joining the mainline (possibly in the 1990's).

The end of the fencing can be seen at the bottom of the picture.

View Looking Towards the Main Manchester - Liverpool Railway

A signal box was sited here in WW2 to control entry into BRD site. The branch line had large volumes of traffic in WW2. The signal box was closed on the 24th of October

1965 and replaced by a 3 lever ground frame released by Widnes East.

The ground frame was out of use by May 1993 when the base closed

A disused semaphore home signal close to the rail junction

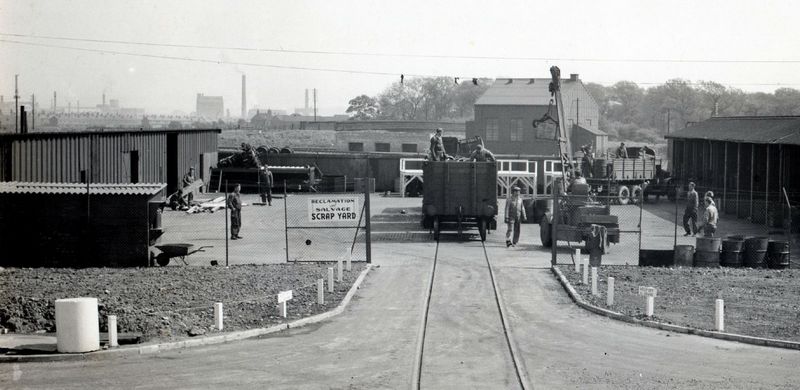

This is the Reclamation Scrap Yard.

The tall building behind the crane is the locomotive shed.

The bridge in the centre of the photo is going across the main Manchester to Liverpool railway line and beyond the bridge on the horizon you can see Lever Brothers/Crossfields building.

Ohio Grove railway bridge is out of site behind the houses.

All the roads on this new estate have an American connection.

This for instance is named Ohio Grove & this photo taken in 2014 by

me & Gary is roughly where the scrapyard was back in WW2

WW2 BRD the railway bridge with the houses off Ohio grove in the background.

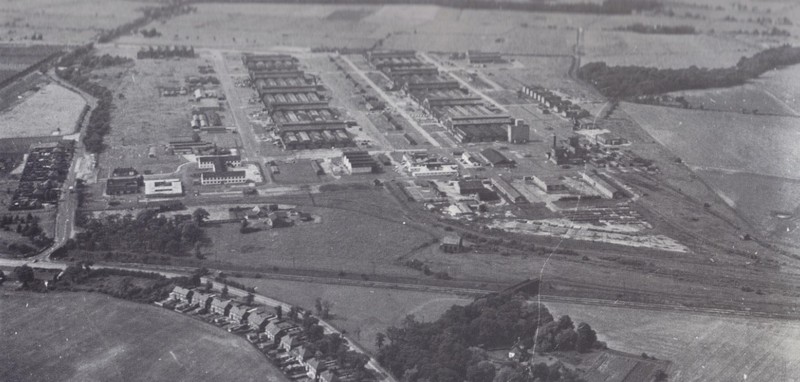

BRD site photo taken in 1960 by the US army looking north.

The Manchester to Liverpool railway line can be seen across the bottom of the photo

the railway bridge and locomotive shed are visible where Ohio grove is today.

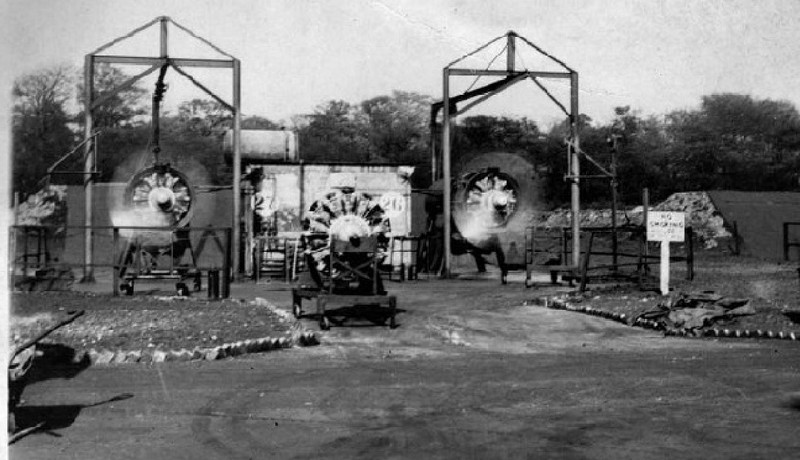

Engine Test Beds

Pratt & Whitney 1830's Aircraft Radial Engines Running

on Their Test Blocks on BRD Site During WW2.

They ran 24 hours a day 7 days a week

in the open air regardless of the weather

Aerial Photo of BRD Site Taken Just After WW2 During

1947 - Note the Camouflage on the Workshop Rooftops

This is the back of the engine test beds 2014

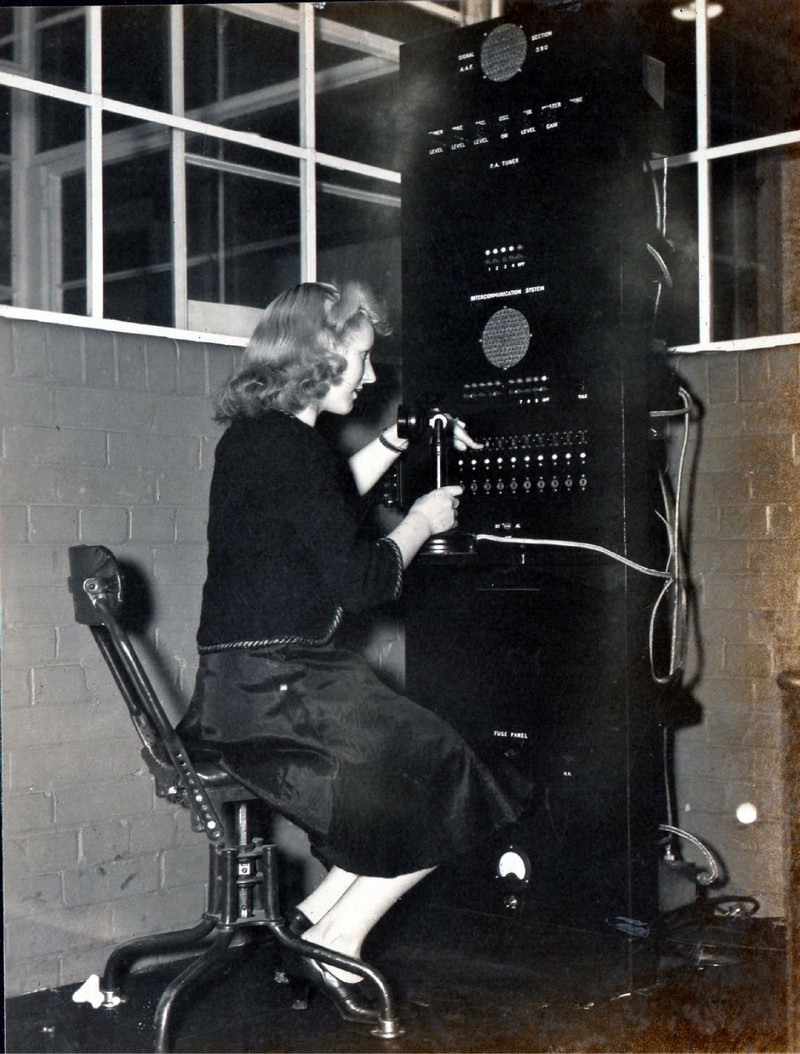

Photo 4 Speech Broadcasting or Public Address Station

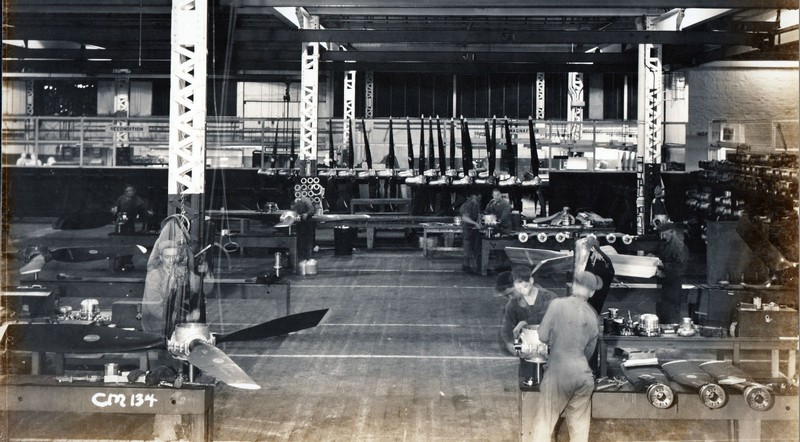

Photo CM134 Prop Section

CM132 Prop Shop

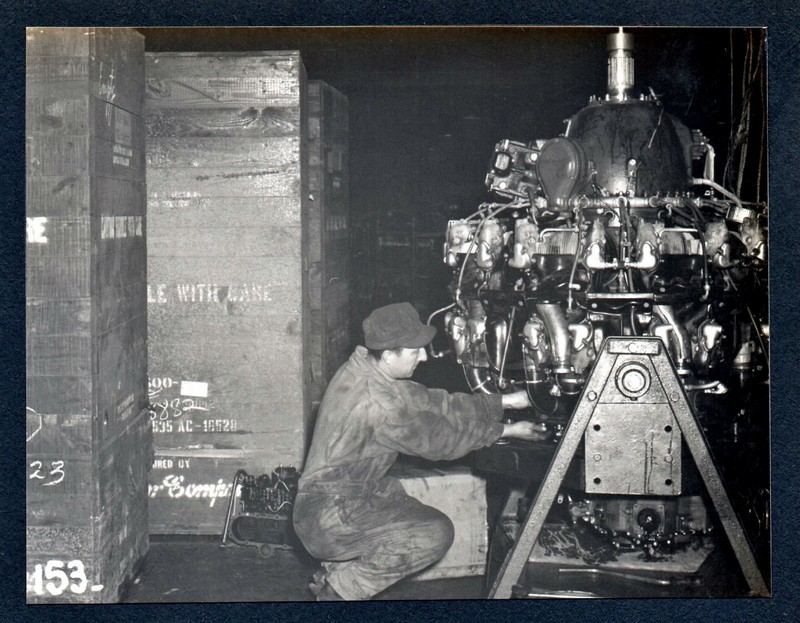

Photo 153 Engine Overhaul

Dinghy Inspection

Fabric Store

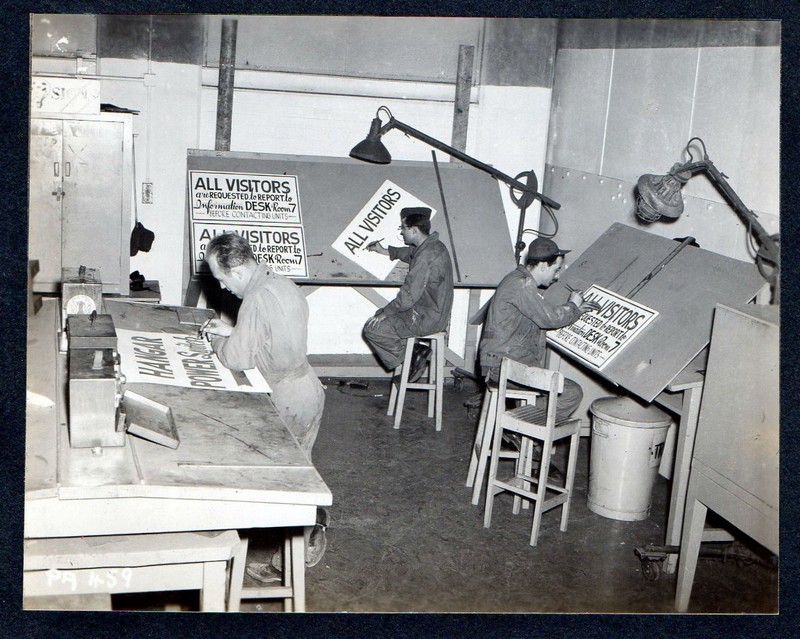

Photo PA459 Sign Writing

Photo 121 Maintenance Office

Photo 138 Maintenance Office

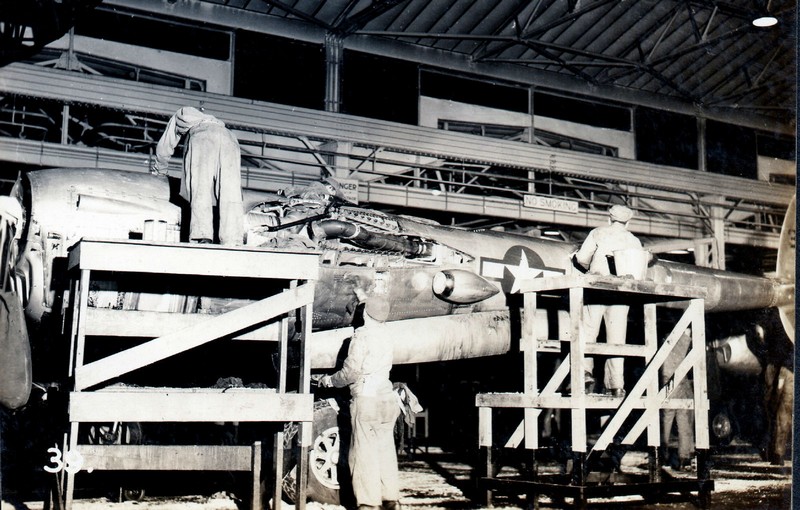

Photo 39 P38 Assembly

BRD Photo 113 P38 Lightning Maintenance

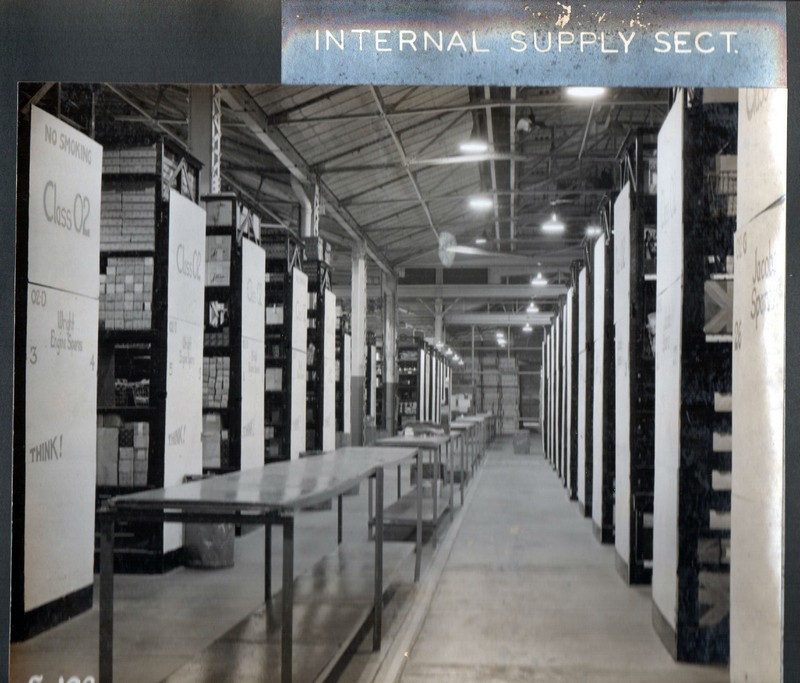

Internal Supply

Photo 167 Engine Assembly

Photo 124 Accident Repair

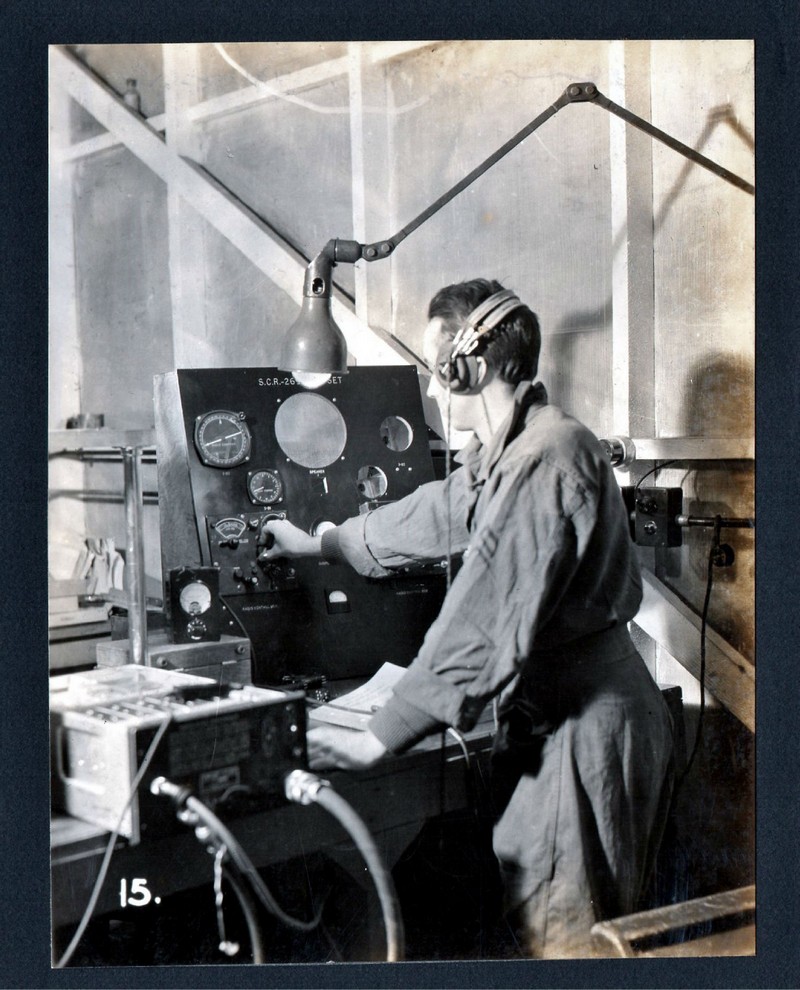

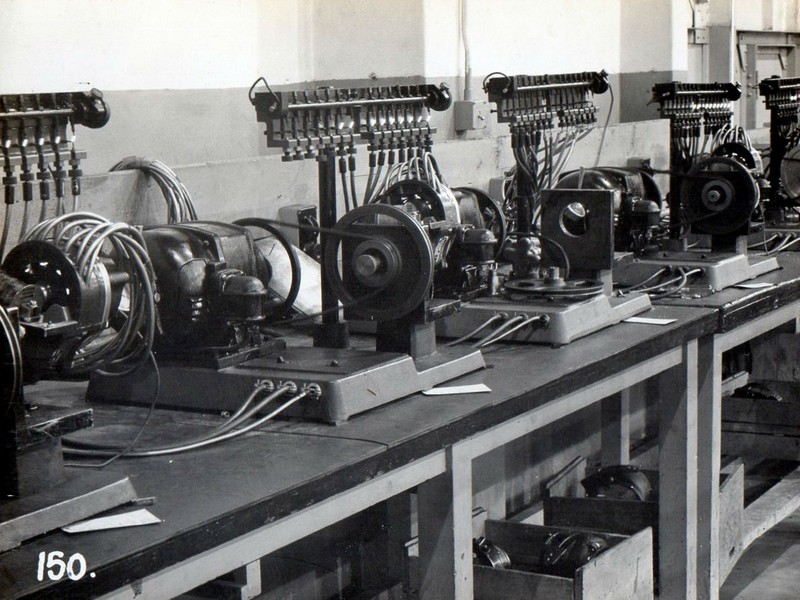

Photo 15 Instrument Testing

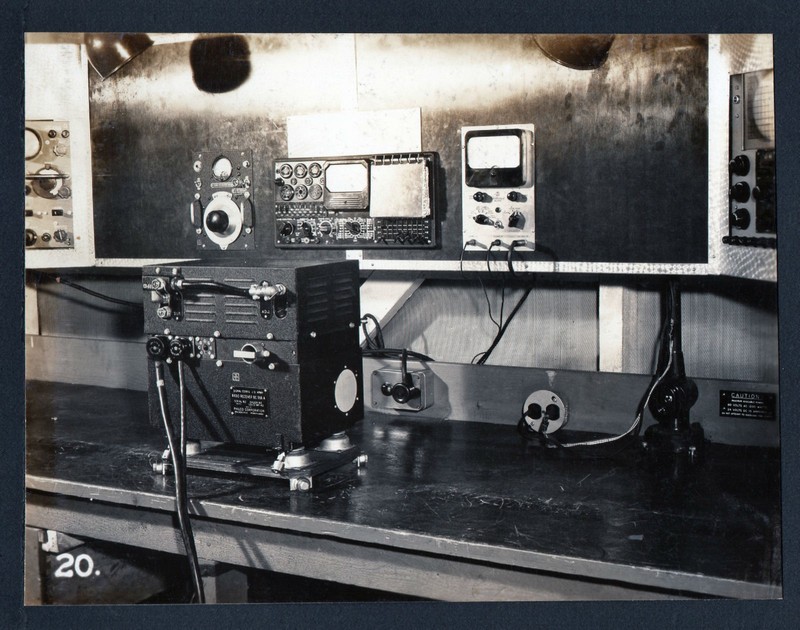

BRD Photo 28 Testing Equipment

BRD Photo 172 Testing Equipment

(Water Injection Pressure Testing)

The quality of fuel in England may have been poor, TEL (tetraethyl lead) fuel additive appeared to condense inside engine induction manifolds, causing detonation (destructive explosion of fuel mixture rather than controlled burning).

Improved turbo supercharger intercoolers appeared on the J model P-38. These devices greatly reduced manifold temperatures but this encouraged TEL condensation in manifolds during cruise flight and increased spark plug fouling.

Using water injection to minimize detonation might have reduced these engine problems. Both the Republic P-47 Thunderbolt and the North American P-51 Mustang (see NASM collection) were fitted with water injection systems as well.

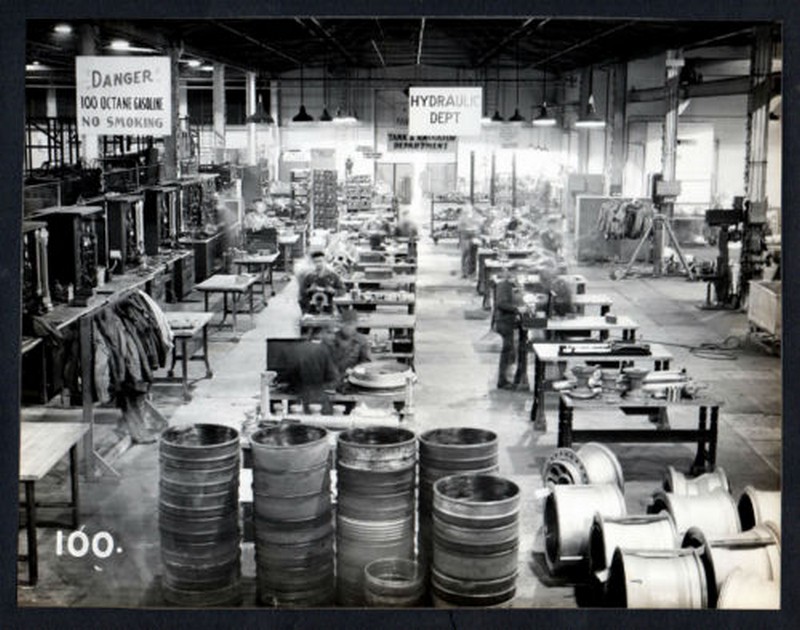

BRD Photo 100 Hydraulic Department

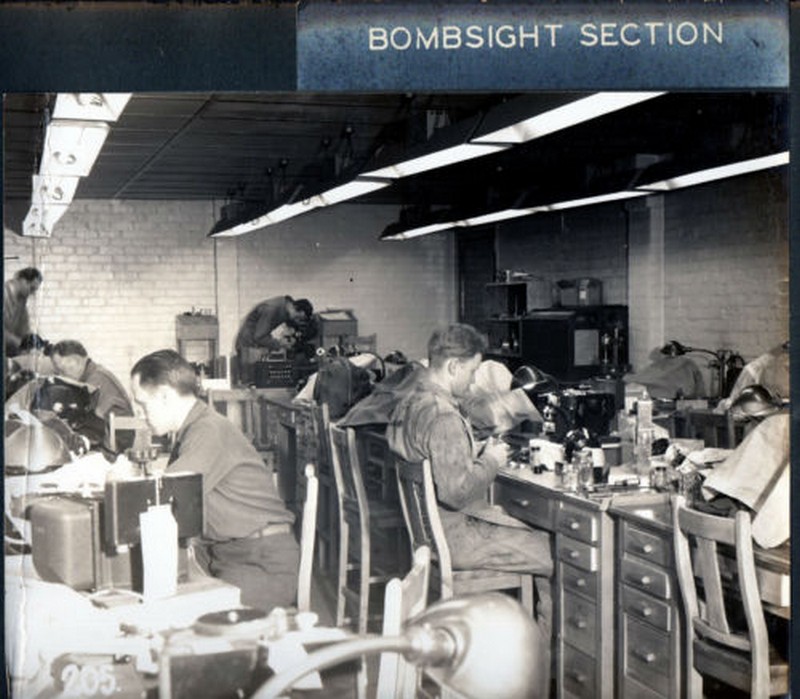

Bombsight Section Workshop

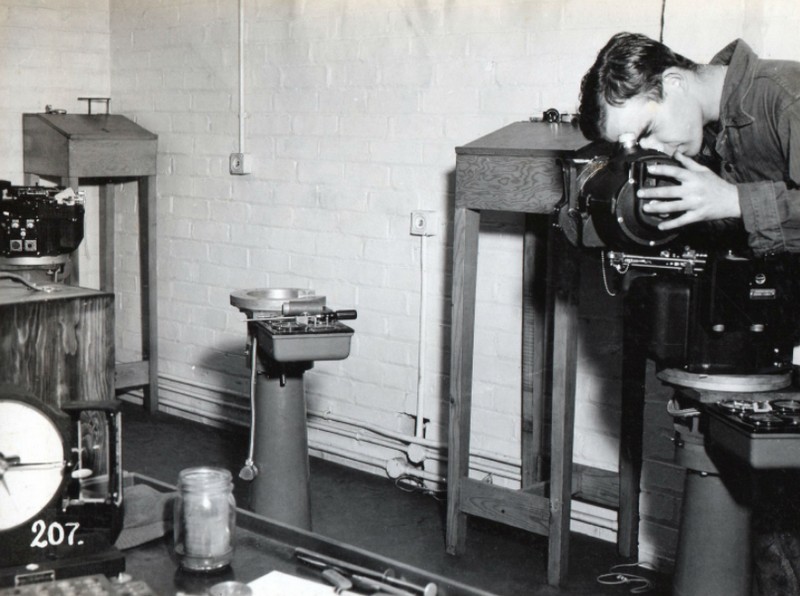

Bombsight Section Callibration

BRD Airframe Erection Workshop

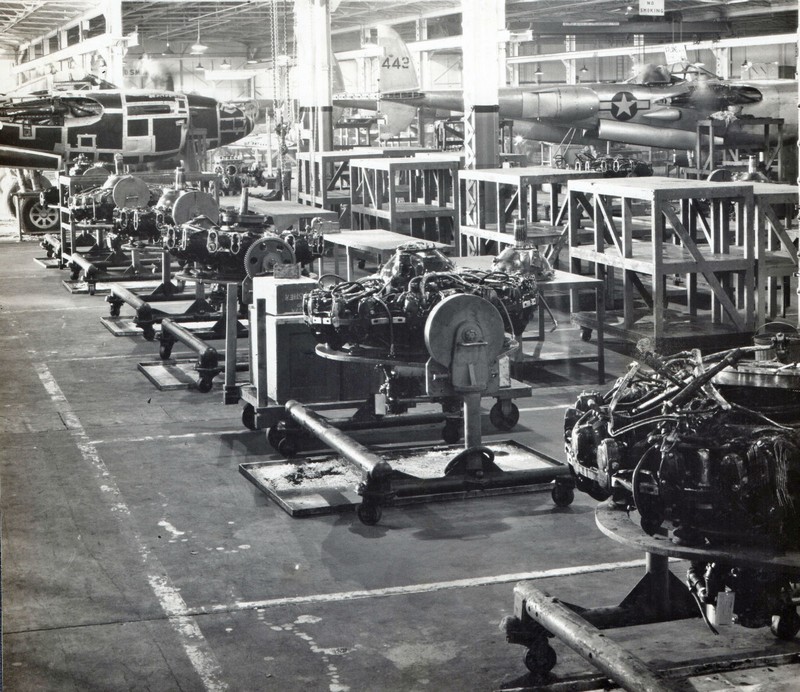

BRD Photo 173 Engine Storage and Maintanence Line

BRD Doping Section.

BRD Photo 39 Oxygen Department

BRD Photo 121 Canopy Repair

BRD Photo 84 Machine Shop

BRD Photo 155 Engine Assembly

Photo 131 Engine Maintenance

Photo 134 Maintenance

BRD Photo 141

Photo 127 Engine Maintenance

P-38 Lightning Maintenance Photo 127

Piper L-4 Grasshopper 2 Seat Light Observation/

Communication Aircraft Being Unpacked and Assembled

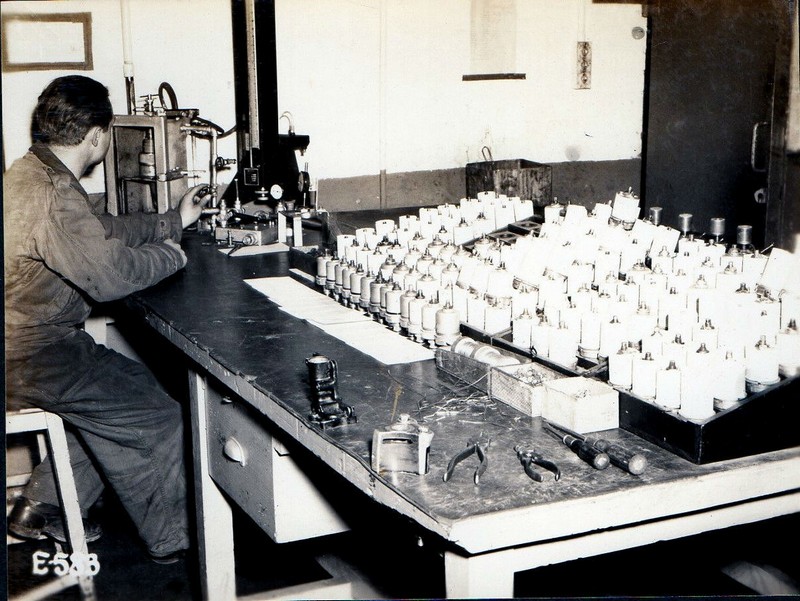

Photo E583 Radio Repair Shop

American Aircraft at Burtonwood That

Entered RAF Service 1939 - 1945

Maryland Mark I AR7381945

Maryland Mark I, AR738, on the ground at the Burtonwood Repair Depot, Lancashire, following assembly.

AR738 was one of fifty Marylands from a French Government contract which was acquired by the British Purchasing Commission in the United States following the surrender of France and designated the Maryland Mark I.

Many of these aircraft were employed on strategic reconnaissance in Malta and the Middle East but, although AR738 was flown to No. 107 Maintenance Unit at Kasfareet, Egypt, there is no record of its operational use in the theatre.

It later crashed on landing at El Firdan, Egypt, in November 1942.

Photographer unknown

Photograph credit to the IWM for non-commercial use.

Maryland Mark I AR703

Maryland Mark I, AR703, on the ground at No. 37 Maintenance Unit, Burtonwood, Lancashire, November 1941.

One of the original batch of Martin 167Fs was ordered by the French government and diverted to the RAF after the surrender in 1940,

AR703 undertook to handle trials at the Aeroplane and Armament Experimental Establishment, Boscombe Down, Wiltshire, before being despatched to the Middle East for operational service.

The Photo was taken by an official RAF photographer

Photograph credit to the IWM for non-commercial use

Havoc Mark I (Turbinlite) AW400

Havoc Mark I (Turbinlite), AW400, on the ground at Burtonwood Repair Depot, Lancashire.

This aircraft served with:

Nos. 1422 and 1454 (Turbinlite) Flights

and with 1459 (Turbinlite) Flight/No. 538 Squadron RAF, before transfer to the USAAF in April 1943.

The Photo was taken by an official RAF photographer.

Photograph credit to the IWM for non-commercial use

Vigilant, HL429

Vigilant, HL429, at No. 37 Maintenance Unit, Burtonwood, Lancashire, following assembly by the Aircraft Storage Unit.

HL429 was tested by the Aeroplane and Armament Experimental Establishment before embarking on a long period of service with:

No. 651 (AOP) Squadron RAF

No. 43 Operational Training Unit

No. 83 Group Communications Flight

The 2nd Tactical Air Force Communications Squadron

and finally with the BAFO Communications Wing in Germany before being struck off charge in March 1946.

The photo was taken by an official RAF photographer.

Photograph credit to the IWM for non-commercial use

Baltimore Mark I, AG688

Baltimore Mark I, AG688, at the Burtonwood Repair Depot, Lancashire, before despatch to the Aeroplane and Armament Experimental Establishment at Boscombe Down, Wiltshire, for flight tests.

The photo was taken by an official RAF photographer

Photograph credit to the IWM.for non-commercial use

Mohawk Mark IV BJ442

Mohawk Mark IV, BJ442, on the ground at Burtonwood, Lancashire, where it was employed in defense of the airfield following its assembly there, November 1940.

This aircraft was one of a number of Hawk 75A-4s originally ordered for the French Air Force, which was taken over by the RAF following the collapse of France.

In 1942, BJ442 was delivered to India for service with No. 155 Squadron RAF.

The photo was taken by an official RAF photographer.

Photograph credit to the IWM.for non-commercial use

Boston Mark III (Intruder), W8325

Boston Mark III (Intruder), W8325, at the Burtonwood Repair Depot, Lancashire, following conversion from a standard Boston Mark III.

The aircraft served with No. 418 Squadron RCAF until 11 April 1943 when it failed to return from a night intruder mission over Melun-Villaroche, France.

The photo was taken by the Ministry of Aircraft Production [MAP]

Photograph credit to the IWM.for non-commercial use.

Boston Mark III (Intruder) W8292

Boston Mark III (Intruder), W8292, at the Burtonwood Repair Depot, Lancashire, following conversion from a standard Boston Mark III.

This aircraft served with No. 23 Squadron RAF and with No. 418 Squadron RCAF before its destruction during an air test in January 1943.

The photo was taken by the Ministry of Aircraft Production [MAP]

Photograph credit to the IWM for non-commercial use.

Havoc Mark II (Night Fighter) AH522

Havoc Mark II (Night Fighter), AH522, on the ground at the Burtonwood Repair Depot, Lancashire, following conversion from a Boston Mark II.

AH522 served with No. 85 Squadron RAF, followed by the Telecommunications Flying Unit with whom it was written off following a landing accident at Defford in November 1943.

The photo was taken by the Ministry of Aircraft Production [MAP]

Photograph credit to the IWM.for non-commercial use.

Martin Maryland Mark I AR725

Martin Maryland Mark I, AR725, on the ground, probably at Burtonwood, Lancashire.

One of a batch of fifty aircraft taken over from a French contract after the German invasion, AR725 served with No. 203 Squadron RAF in the Middle East before crashing on a ferry flight to join No. 69 Squadron RAF in Malta.

The photo was taken by an official RAF photographer

Photograph credit to the IWM for non-commercial use

Boston Mark II (Turbinlite) AH457

Boston Mark II (Turbinlite,) AH457, on the ground at Burtonwood Repair Depot, Lancashire.

This aircraft served with No, 1422 (Night Fighter) Flight, 1457 (Fighter) Flight, and finally with No. 536 Squadron RAF.

The photo was taken by the Ministry of Aircraft Production [MAP]

Photograph credit to the IWM for non-commercial use

Argus Mark I HM164

Argus Mark I, HM164, on the ground at the Burtonwood Repair Depot, Lancashire.

After service with the Aeroplane and Armament Experimental Establishment, the aircraft was transferred to the Air Transport Auxiliary.

The photo was taken by an official RAF photographer.

Photograph credit to the IWM for non-commercial use.

<-------- Click Here to Go Back to Burtonwood Home Page

|